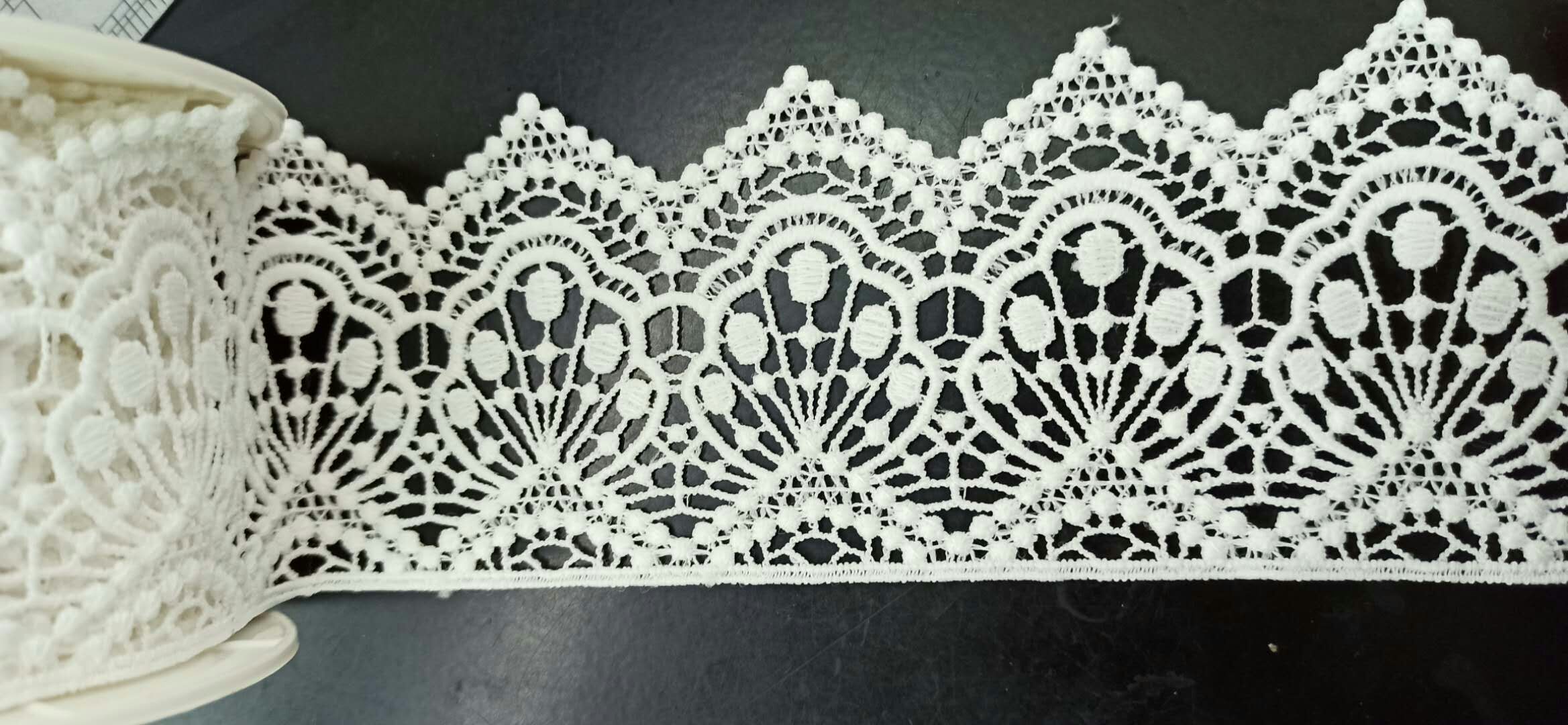

With the progress of science and technology and consumers' increasing awareness of environmental protection, traditional clothing accessories are undergoing a revolutionary change. Among them, the "new water-soluble cotton lace barcode" stands out with its unique working mechanism and significant advantages, and has become a hot topic in the industry.

This innovative product combines cotton material with dissolvable technology while integrating an advanced barcode management system. When applied to clothing, the bar code can not only provide accurate information recording function in the processing stage, but also completely disappear in the later cleaning process without leaving any traces. This characteristic makes it particularly suitable for high-end custom clothing and assembly line operations that require high-precision tracking.

Today, when the world advocates green development, the choice of sustainable and environmentally friendly raw materials has become the strategic focus of major brands. The emergence of the "new water-soluble cotton lace bar code" is just in line with this trend. Due to the use of natural fibers as the main component, coupled with a special chemical treatment process to make it have good biodegradability, so in the entire life cycle will not cause environmental pollution problems.

In addition, its non-residue characteristics and convenient operation also provide users with higher flexibility and lower cost compared to other types of labeling or identification systems. This is ideal for businesses looking to reduce their carbon footprint and maintain their brand image.

From the perspective of the production process, another major benefit of the "new water-soluble cotton lace barcode" is the great improvement in efficiency. Through the built-in digital information coding scheme, each piece of fabric can be given a unique identity ID, thus realizing the possibility of automatic monitoring and management in the whole process.

This means that factory managers can view inventory status, batch ownership and even the progress of specific processes in real time through scanning equipment, greatly reducing the time cost required for manual verification and improving data accuracy. In this way, both small-scale workshops and large-scale industrial production lines can benefit greatly.

In addition to the technical advantages mentioned above, the "new water-soluble cotton lace barcode" can also play an important role in the quality management of finished products. Through the data collection and analysis of each link, manufacturers can quickly locate the source of potential defects and adjust the relevant parameter settings in time to ensure that the quality of the final product is always under control.

At the same time, consumers can also use the scan code inquiry service to obtain more information about the story behind the purchased goods, including but not limited to the specific information about the place of purchase of raw materials, production process steps and even employee benefits. Such transparency initiatives will undoubtedly help to build more trusting ties.

To better demonstrate the practical value of the "new water-soluble cotton lace barcode", let's take a look at some success stories where this solution has been successfully deployed. After an internationally renowned sportswear brand fully implemented the technology in its latest series of development projects, it found that the operation time of the entire supply chain was reduced by nearly 30%, and the customer satisfaction score increased by more than two percentage points.

Another example comes from a small and medium-sized business owner who focuses on children's clothing. He told us that since the switch to this system, not only has the proportion of operating expenses been reduced, but also the opportunity to win multiple long-term cooperative orders due to accurate tracking capabilities. Thus, whether you are a large multinational companies or start-up team members, there are opportunities to get tangible benefits.